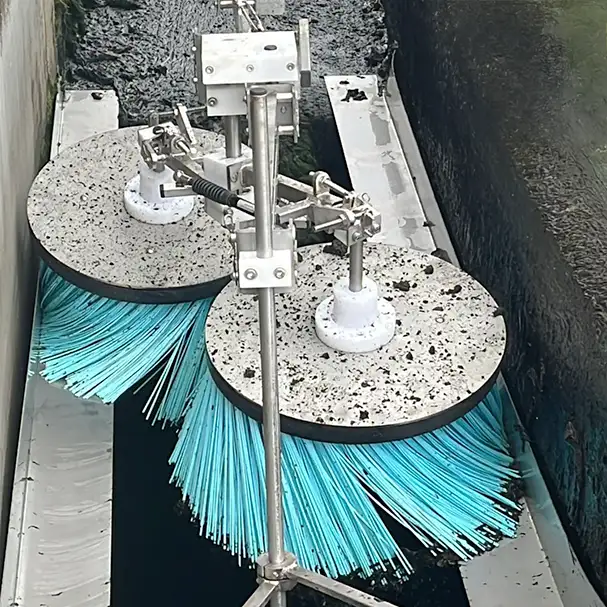

Our solution is mounted on the vertical section of the scraper bridge, which is driven by a gear motor and a drive wheel.

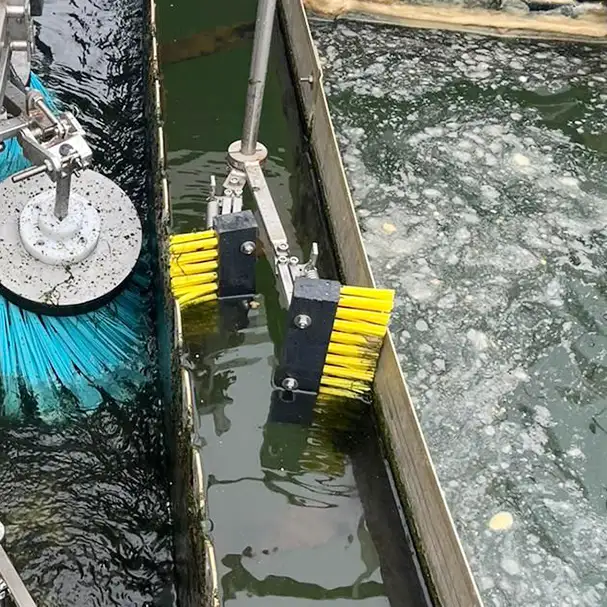

The cleaner operates without electricity, using only the inertia of the scraper bridge, fully meeting both technical and environmental constraints.

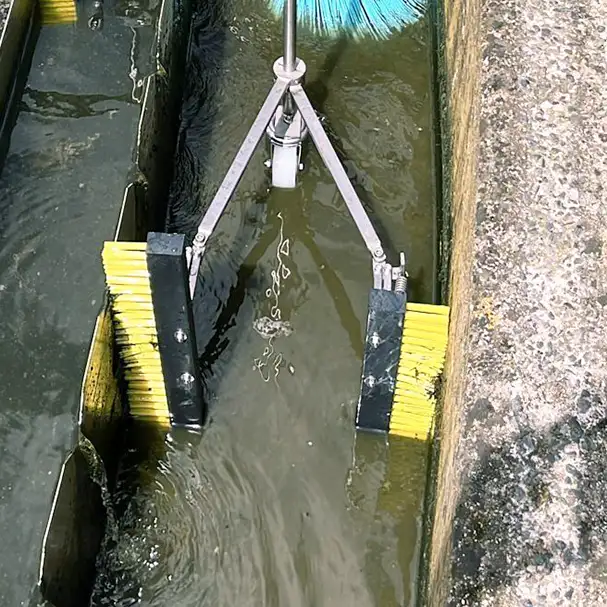

Thanks to its articulated design, the system adapts easily to site-specific requirements and the constraints of all types of installations.

The structure is made of 304L stainless steel. Bearing housings and clamps are made of PA66 (or equivalent). All ball bearings are stainless steel and sealed.

The overall weight of the system ensures constant pressure of the rotating brushes against the channel bottom, while automatically compensating for level irregularities in the launder.

Our experience with this technology since 2003, combined with precise adjustments

carried out by our technician, ensures the rotation of the brushes in two opposite

directions whenever the scraper bridge is in operation.